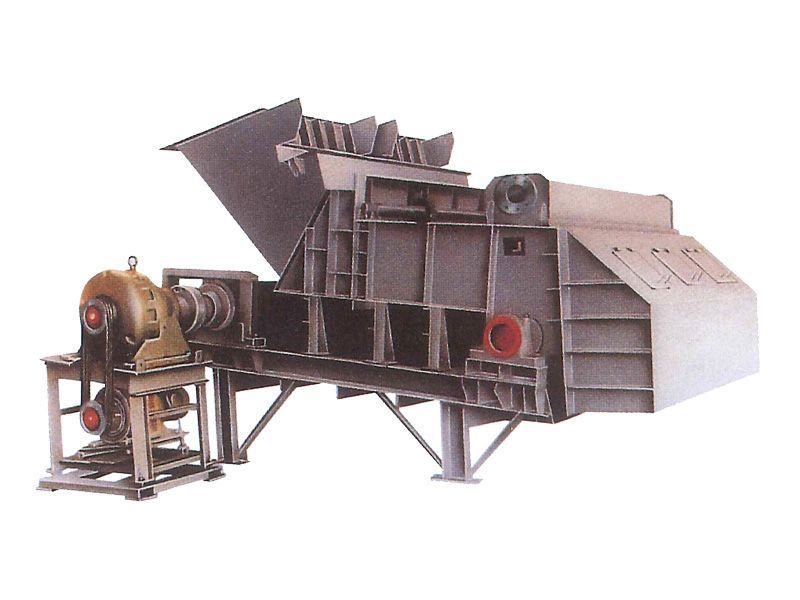

Processing and Manufacturing of Coal Preparation Equipment: Integration of Technology and Innovation

In the coal industry, the processing and manufacturing of coal preparation equipment is not only related to production efficiency, but also directly affects the quality and economic benefits of coal. As the core of this field, the processing and manufacturing of coal preparation equipment combines exquisite craftsmanship and continuous innovation, which provides strong support for the sustainable development of the coal industry.

The processing and manufacturing of coal preparation equipment is first reflected in the selection of materials. High-quality raw materials are the basis for manufacturing high-quality coal preparation equipment. Modern coal preparation equipment usually uses wear-resistant, corrosion-resistant, high-strength materials to ensure that the equipment can run stably for a long time in harsh working environments.

In terms of manufacturing process, the processing and manufacturing requirements of coal preparation equipment are fine and rigorous. From design to production, every link needs to be strictly controlled to ensure that the performance and accuracy of the equipment meet the predetermined standards. At the same time, with the progress of science and technology, more and more advanced technologies are applied to the manufacture of coal preparation equipment, such as CNC machine tools, laser cutting, etc., which greatly improves the manufacturing accuracy and efficiency of the equipment.

However, fine craftsmanship alone is not enough. In the processing and manufacturing of coal preparation equipment, innovation is equally important. With the continuous changes in the coal market and the increasingly stringent environmental requirements, coal preparation equipment needs to constantly adapt to new needs. Therefore, manufacturers need to constantly explore new design concepts, new manufacturing processes and new material applications to promote the upgrading of coal preparation equipment.

In general, the processing and manufacturing of coal preparation equipment is a process of integration of technology and innovation. It requires not only exquisite manufacturing technology to ensure the quality and performance of the equipment, but also continuous innovation to adapt to the changes of the market and meet the needs of customers. Only in this way can we create more advanced and effective coal preparation equipment and contribute to the sustainable development of the coal industry.

Key words:

RELATED INFORMATION

Coal preparation equipment: the key force of coal processing

2024-04-11

2024-04-11

2024-04-11