In the manufacture of coal preparation equipment, which technologies have a greater impact on quality?

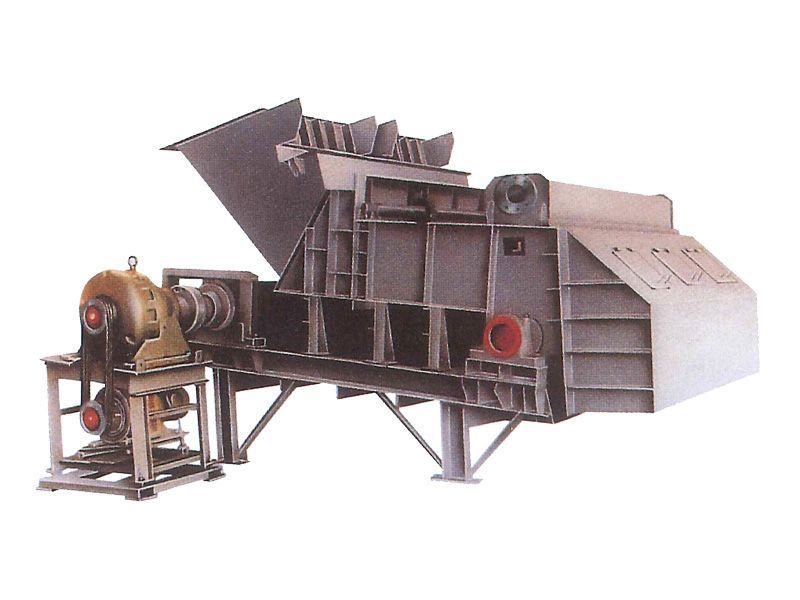

In the manufacturing process of coal preparation equipment, a variety of technologies have a significant impact on the quality of the equipment. Here are some of the key technologies that have an impact on quality:

First of all, high-precision machining technology is the key to ensure the precise coordination of various components of coal preparation equipment. Whether it is gears, bearings or other key components, its accuracy directly affects the overall performance and stability of the equipment. Therefore, the application of advanced machining technology such as high-precision CNC machine tools and laser cutting is very important to improve the quality of equipment.

Secondly, welding technology is also an important factor affecting the quality of coal preparation equipment. There are a large number of welding parts in the coal preparation equipment, and the welding quality is directly related to the strength and sealing of the equipment. The use of advanced welding processes and equipment, such as automated welding robots and laser welding technology, can greatly improve the quality and efficiency of welding.

In addition, intelligent control technology is of great significance for improving the automation level and operation convenience of coal preparation equipment. By integrating intelligent elements such as sensors, PLC control systems and human-machine interfaces, the functions of remote monitoring, fault diagnosis and automatic adjustment of the equipment can be realized, thereby improving the operation stability and production efficiency of the equipment.

At the same time, the application of wear-resistant and corrosion-resistant materials is also the key to improve the quality of coal preparation equipment. In the harsh working environment, the equipment materials need to have good wear resistance and corrosion resistance to ensure the long-term stable operation of the equipment. Therefore, selecting high-quality raw materials and adopting advanced surface treatment technologies, such as spraying and coating, can effectively improve the durability of the equipment.

Finally, the design concept and process innovation are also important factors affecting the quality of coal preparation equipment. By continuously optimizing the design scheme and adopting new structure and technology, the performance and quality of the equipment can be further improved. At the same time, combined with market demand and environmental protection requirements, continuous innovation of products is also the key to enhance the competitiveness of equipment.

In summary, technical factors such as high-precision machining technology, welding technology, intelligent control technology, the application of wear-resistant and corrosion-resistant materials, as well as design concepts and process innovation, have a significant impact on the quality of coal preparation equipment. In the manufacturing process, these factors need to be considered comprehensively to ensure the high quality and excellent performance of the equipment.

Key words:

RELATED INFORMATION

Coal preparation equipment: the key force of coal processing

2024-04-11

2024-04-11

2024-04-11