What is the selection principle of wear-resistant and corrosion-resistant materials in coal preparation equipment?

The selection principles of wear-resistant and corrosion-resistant materials in coal preparation equipment mainly include the following aspects:

First of all, the economic principle is the basis for the selection of coal preparation equipment materials. On the premise of meeting the technical performance requirements, the material with reasonable price and reliable quality should be selected first. This requires a comprehensive consideration of material procurement costs, processing costs, and post-maintenance costs to optimize the total cost of the equipment life cycle.

Second, the principle of security is essential. In the operation of coal preparation equipment, safety is the primary consideration. Therefore, the selected wear-resistant and corrosion-resistant materials must meet safety standards and have good mechanical properties and chemical stability to ensure the safe and stable operation of the equipment in harsh environments.

In addition, the principle of environmental protection can not be ignored. With the increasing awareness of environmental protection, the material selection of coal preparation equipment also needs to meet the requirements of environmental protection. Preferential selection of environmentally friendly materials, reduce the impact on the environment, to achieve green production.

At the same time, the technical principle is the key to ensure the performance of the equipment. The selected wear-resistant and corrosion-resistant materials should have good wear-resistant and corrosion-resistant properties and be able to meet the specific work requirements of the coal preparation equipment. For example, for components that need to be exposed to corrosive media for a long time, materials with excellent corrosion resistance should be selected.

Finally, the principle of adaptability is also a factor to consider. Different coal preparation equipment and process flow have different requirements for materials. Therefore, when selecting wear-resistant and corrosion-resistant materials, it is necessary to fully consider the actual situation of the equipment and the characteristics of the process flow, and select materials with strong adaptability.

In summary, the selection principle of wear-resistant and corrosion-resistant materials in coal preparation equipment is a decision-making process that comprehensively considers many factors such as economy, safety, environmental protection, technology and adaptability. Through scientific and reasonable selection of materials, the performance of coal preparation equipment can be ensured to be stable, safe and reliable, environmentally friendly and effective.

Key words:

RELATED INFORMATION

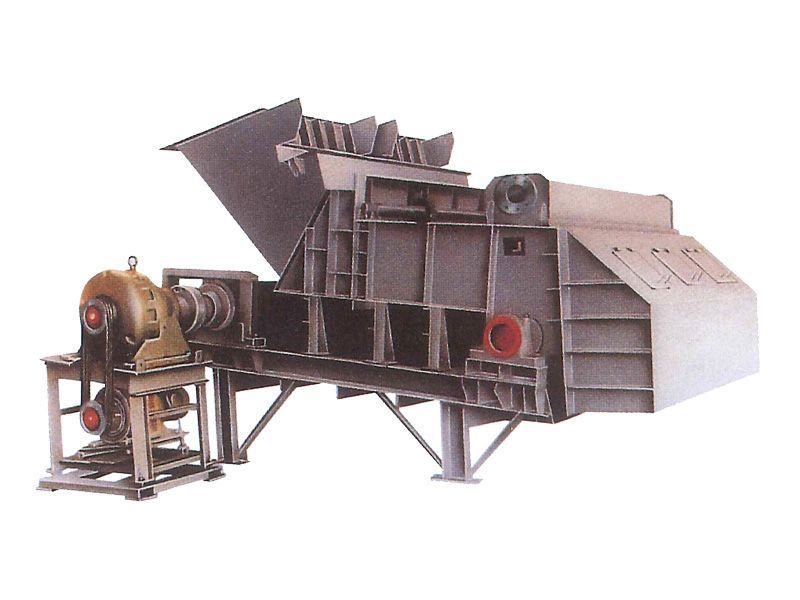

Coal preparation equipment: the key force of coal processing

2024-04-11

2024-04-11

2024-04-11