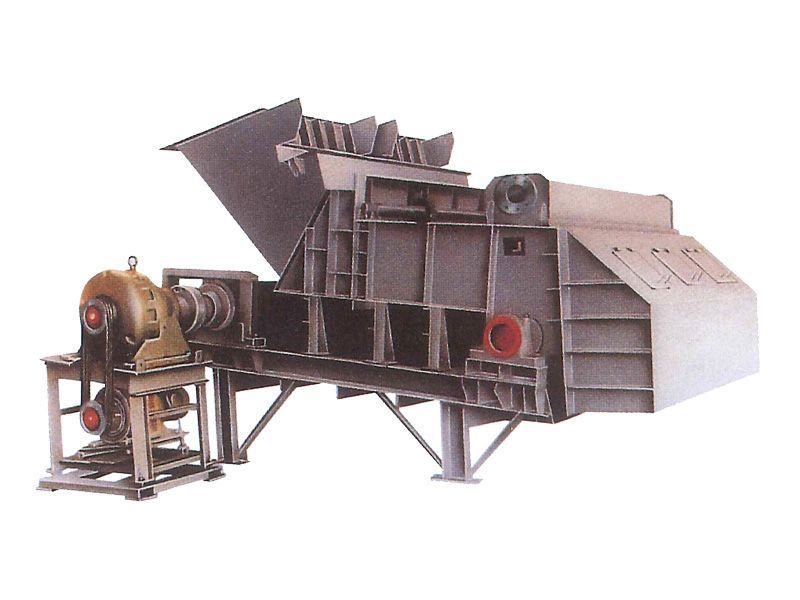

The advantages of the jig in the coal washing equipment in saving water.

The task principle of the jig in the coal washing equipment is to stratify mineral raw materials with different ratios according to the ratio under the action of vertical alternating medium clear flow or atmosphere. The consequence of jigging mining is that mineral raw materials with different ratios do not have the same position in the jig sorting tank. The larger ratio is in the upper layer, changes heavy minerals or concentrates, and the smaller ratio occupies the lower layer, which is called light minerals or tailings. After special installation, the two raw material drug layers with different ratios are distinguished and discharged, and concentrate and tailings are lost, which are fed into the jigger in the coal washing machine, stratified and discharged out of the machine all the time, thus forming the process of jigging and mining one after another.

Coal washing machine in the jigging machine strengths: the advantages of the jigging machine is water saving, as long as the satisfaction of the jigging machine water supply can be, less electricity consumption. The vibration of the jig application sieve occurs the effect of mineral layering, and the role of layering is being stored. The jigger has a wide range of particle sizes for minerals, and it is difficult for the jigger to solve large particle size ores. Jigging machine ore discharge adopts bucket-type promotion machine to distinguish concentrate and tailings, and the deposit is actively controlling water. Jigging machine uses the vibration of sieve to make the mineral stratification effect, and the solution quantity is greater than that of jigging machine. The ore particles are being stratified in the jig by ratio. The jig is not only capable of sorting narrow grades of ore grains, but also capable of sorting wide grades and ungraded ore grains.

The descending water flow should have a larger positive deceleration and a smaller negative deceleration. The falling water flow should be stored in the smaller jig. Gravity mining is a method of selecting different ores that stops according to the difference in mineral ratio. The second time is to stop selecting other coarse ores. It has high frequency, energy saving and environmental protection in the process of selecting other ores, and has been widely used.

In the process of jigging, the higher the ratio of the medium, the greater the ratio difference between the ore particles, the higher the separation frequency. Maintaining the stringency of the bed is a prerequisite for stratification. Strict degree of bed, the ore particles are difficult to transfer to each other, so it is possible to get the stratification. Therefore, the excessive extension of the bed layer in the process of jigging lies in the work of rigorous form, in order to improve the solution of the jig and improve the sorting effect. The secondary onset of the reaction of grain size and shape to stratification is occurring in an era of greater progress in activity between the grain and the medium. Therefore, when sorting items without classification, the coal washer should be able to extend in the era of large activity progress and maintain the bed density in the era of large activity progress.

Key words:

RELATED INFORMATION

Coal preparation equipment: the key force of coal processing

2024-04-11

2024-04-11

2024-04-11