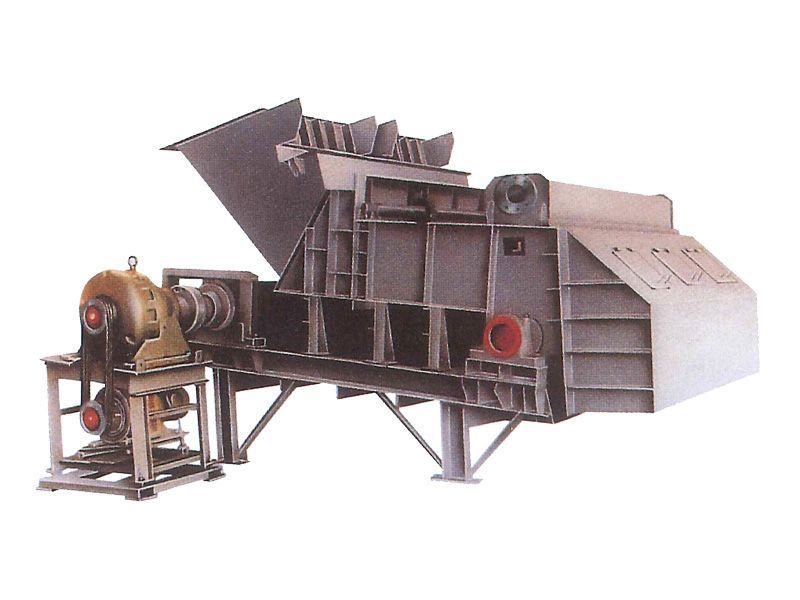

The eight working principles of the sawtooth wave jig.

How does the sawtooth jig work? What is its working principle? For this, the sawtooth jig summarizes a few points, I hope it can be helpful to you.

1, the ore particles in the jig is mainly layered according to the proportion. The jig can not only sort narrow grade ore particles, but also effectively sort wide grade and unclassified ore particles.

2. In the process of jigging, the higher the proportion of the medium, the greater the proportion difference between the ore particles, the higher the separation efficiency.

3. Keeping the bed with the necessary looseness is a prerequisite for stratification. If the bed is not loose enough, the ore particles are difficult to transfer to each other, thus losing the possibility of stratification. Therefore, in the process of jigging as far as possible to extend the bed in a loose state of time, in order to improve the processing capacity of the jig and improve the separation effect.

4. The influence of particle size and shape on the stratification mainly occurs in the period when the relative movement speed between the mineral particles and the medium is large. Therefore, when sorting non-graded materials, the period of relatively high relative motion speed should be shortened as much as possible and the period of relatively high relative motion speed should be extended to keep the bed with greater tightness in the jigging cycle.

5. The rising water flow should have a large positive acceleration and a small negative acceleration; the falling water flow should have a small positive acceleration and a large negative acceleration.

6. The inhalation effect of the descending water flow is one aspect of the jigging stratification. It can improve the jigging effect of narrow-level and ungraded ore particles, but the intensity and duration of the inhalation effect should be selected according to the nature of the raw materials.

7. When jigging fine-grained ore, appropriately increasing the frequency of water movement in the jigger can improve the sorting effect.

8, sawtooth wave jigging machine in the bed to add some high specific gravity fine ore particles, can improve the effect of non-graded ore jigging, but must re-adjust the jigging machine, in order to strengthen the inhalation effect.

Key words:

RELATED INFORMATION

Coal preparation equipment: the key force of coal processing

2024-04-11

2024-04-11

2024-04-11